ABYC Standards Week shapes DIY boat safety and repair expectations

ABYC's 17th Standards Week is underway in Charleston, updating standards that affect electrical, fuel, hull and fire systems for recreational boats. These changes matter for owners who work on or evaluate repairs.

The American Boat & Yacht Council opened its 17th annual Standards Week in Charleston (Jan. 12–15, 2026), bringing marine professionals, manufacturers and technical volunteers together to propose, revise and approve standards that govern boat design, systems, repair and maintenance. The meeting is running both in-person and virtually, stressing participation from a broad cross-section of the industry and technical community.

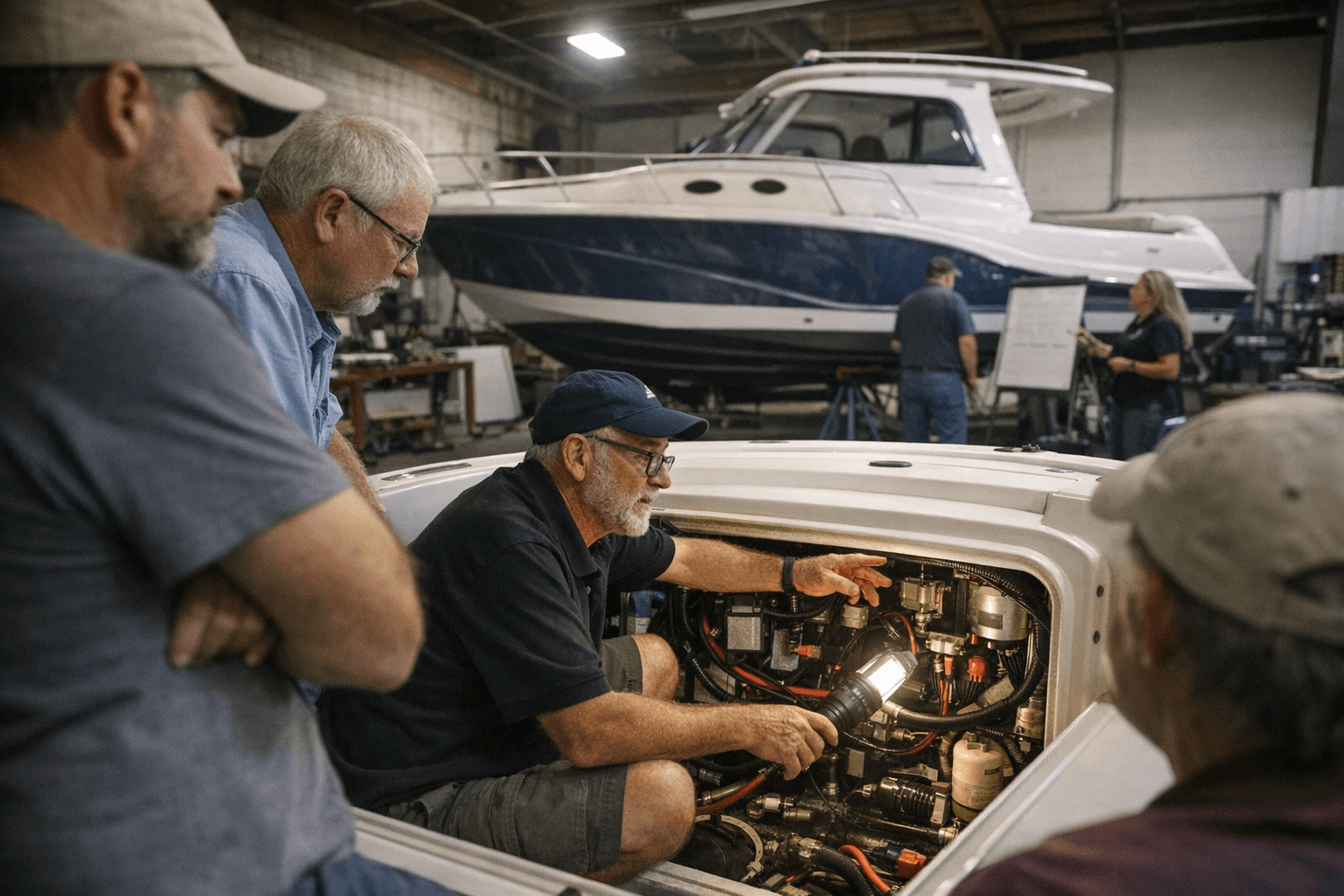

Standards under discussion this week cover areas directly relevant to do-it-yourself boat owners: electrical wiring and battery systems, fuel systems, hull and piping repairs, and fire detection and suppression. The council framed those topics as central to reducing risk and improving safety for recreational boaters and the repair shops that support them. Technical committees use this annual forum to update expectations for workmanship, materials and inspection criteria, which can change how owners perform or evaluate fixes.

Practical takeaways for anyone who turns a wrench or a heat gun in a bilge start with electrical guidance. Check ABYC electrical and battery wiring guidance before undertaking marine electrical work, especially when installing batteries, chargers, inverter systems, or upgrading shore power connections. Standards clarify conductor sizing, overcurrent protection, battery enclosure and ventilation considerations, and wiring methods that reduce corrosion and fault risk, details that matter when you want installations to pass inspection or hold up under sea conditions.

Expect updated or new repair expectations to alter accepted practices for hull and system fixes. That means when you patch a fiberglass hull, replace plumbing or repair fuel lines, pay attention to recommended materials, joint methods and inspection points so your work aligns with what surveyors and repair shops will consider acceptable. If a standard now emphasizes a particular repair method or testing protocol, that can affect resale inspections and insurance evaluations.

ABYC also highlighted outreach and training opportunities tied to Standards Week. Webinars and recorded sessions are intended to help owners, yard techs and independent repairers upskill on specific standards and practical application. Take advantage of these sessions to shore up knowledge on common trouble spots like battery installations, fuel shutoffs, bilge detection and fire suppression system checks.

The weekly process of proposing, revising and approving standards matters because small specification changes ripple through how boats are built, fixed and judged safe on the water. The community benefit is clearer expectations and fewer surprises at survey or during a voyage.

The takeaway? Treat ABYC standards as a working checklist. Check electrical and battery wiring guidance before you start projects, factor new repair expectations into how you evaluate fixes, and use webinars or recordings to learn the practical steps that keep systems shipshape. Our two cents? Shore up your wiring knowledge, document your repairs, and when in doubt ask for training or a pro, it's cheaper than fixing a shortcut after a leak or a fire.

Know something we missed? Have a correction or additional information?

Submit a Tip