Closed-loop reference method boosts FFF accuracy without slowing prints

Researchers described a closed-loop reference optimization for FFF that uses on-printer sensing to pre-distort commands so deposited material matches intended geometry.

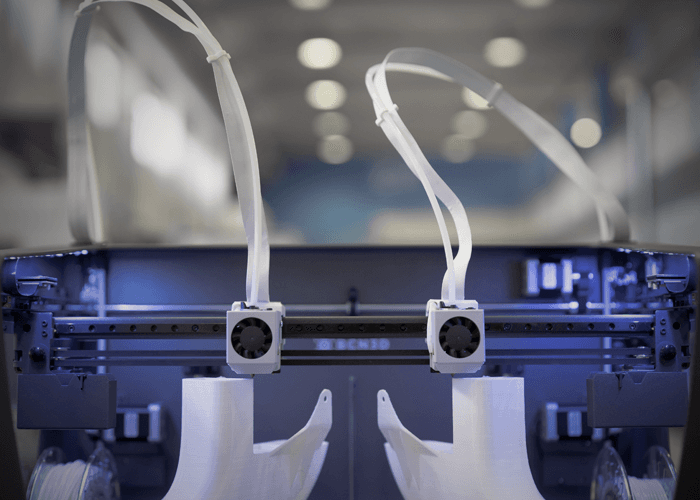

Researchers unveiled a closed-loop reference optimization strategy for fused filament fabrication that shifts the focus from controller tuning to smarter command shaping. Instead of treating slicer output as immutable G-code scripture, the system measures what the printer actually does and alters the commanded trajectory and extrusion setpoints so the deposited plastic ends up where designers intended.

The approach relies on on-printer sensing—encoders, accelerometers, thermistors, and optical systems such as cameras or laser lines—to observe deviations caused by melt lag, nozzle pressure build-up, acceleration limits, and other dynamic effects. Using those measurements, the software learns a mapping from desired geometry to the pre-distorted reference that compensates for time-dependent extrusion behavior. The result: fewer corner blips, rounder holes, and more consistent thin walls at speeds you want to keep.

Two operational modes are described. One is online intra-layer correction that adjusts the reference mid-print as sensors report errors. The other is a layer-to-layer learning loop that updates the next layer’s reference based on observed deviations. Both modes aim to produce the same net effect: the firmware or post-processor issues a different command that accounts for the machine’s practical response, rather than relying solely on feedback control gains to chase errors after they happen.

This is not a magic bullet; implementation depends on reliable sensors and a validated model of extrusion dynamics. Hobby printers will need trustworthy encoders or vision systems and robust thermal sensing to make the learning stable. Where this pays off most is in high-speed or high-precision work and in production or education settings where repeatability matters more than marginal setup time. In those environments, pre-distortion can be more effective than tedious manual tuning of jerk, acceleration, pressure compensation, or extrusion multipliers.

For the community, the practical takeaway is straightforward: closed-loop reference shaping could deliver automatic accuracy improvements without forcing users into deep firmware hacking. The method’s design also makes it a candidate for firmware plugins or slicer-side integrations if developers expose the right interfaces.

Our two cents? Keep an eye on this space and start thinking about reliable sensing for your setup. Once plugins and slicer hooks arrive, you’ll want a calibrated thermistor and a decent positional sensor ready to plug in so your prints behave like your models, not like your printer’s quirks.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip