Complete FDM Maintenance Checklist for Hobbyists: Weekly to Quarterly Care

A compact maintenance checklist lays out weekly, monthly, and quarterly care to keep FDM printers reliable, reduce failed prints, and protect filament and hardware.

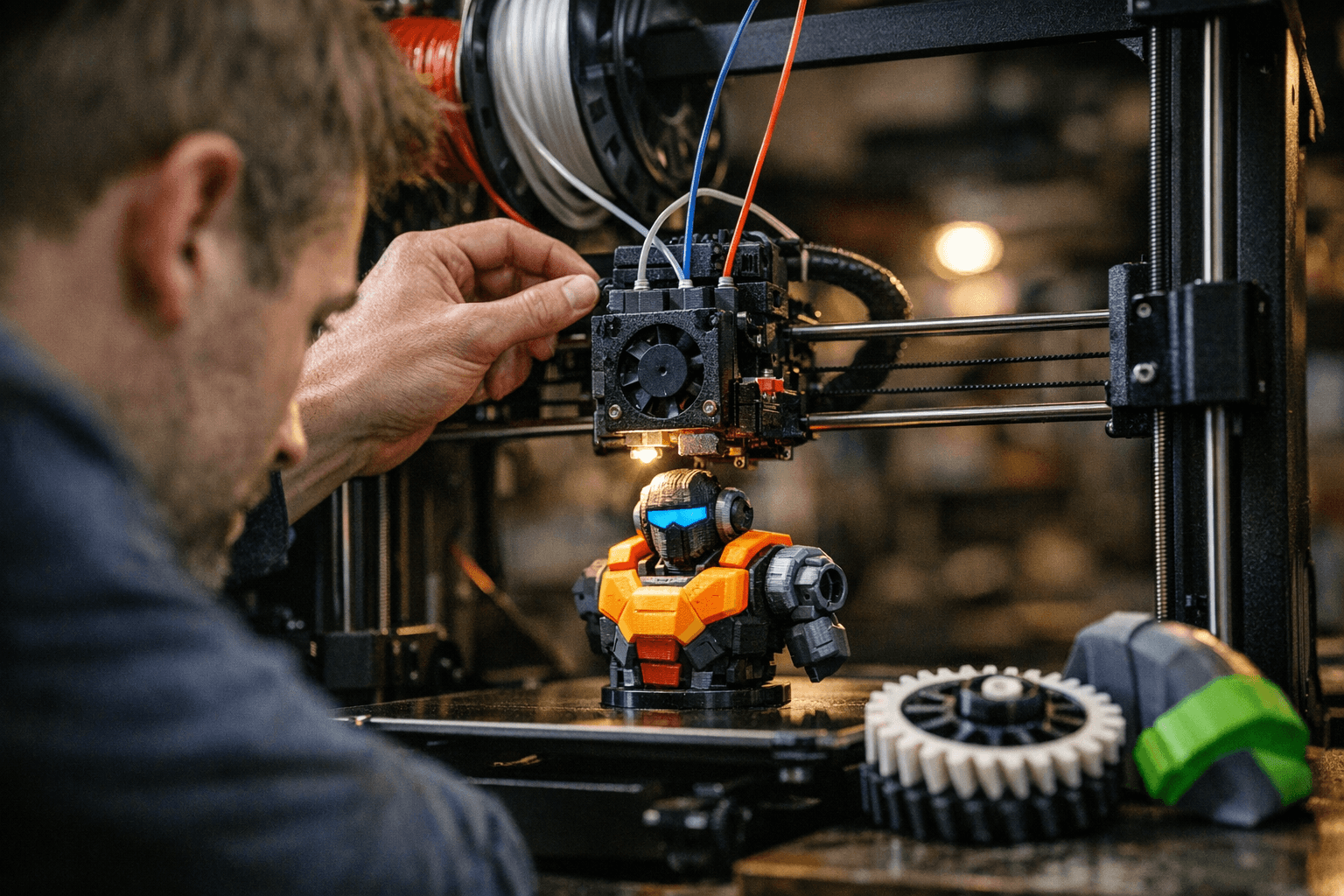

Keeping an FDM printer tuned is the fastest way to turn messy failed prints into reliable parts and fewer late-night reprints. A concise maintenance checklist helps prioritize tasks so a weekend hobbyist or community maker-space can protect nozzles, motion systems, and hygroscopic filament.

Start with weekly maintenance. Clean the print surface to maintain first-layer adhesion and remove oils that cause lifting or stringing. Check filament for dust and signs of moisture; look for brittle strands or popping during extrusion that signal degraded filament. Verify nozzle temperature and extrusion by running a short extrusion test or single-layer print to confirm flow is consistent and the hotend reaches set temperatures.

Move on to monthly checks to catch wear before it causes layer shifts or lost steps. Inspect belts and set tension so they are firm but not over-tightened; belts that are too tight can strain motors and bearings. Lubricate linear rods and lead screws following the printer manufacturer's guidance to avoid excess grease that attracts dust. Tighten pulley grub screws and verify motor couplers are secure to prevent slipping under acceleration.

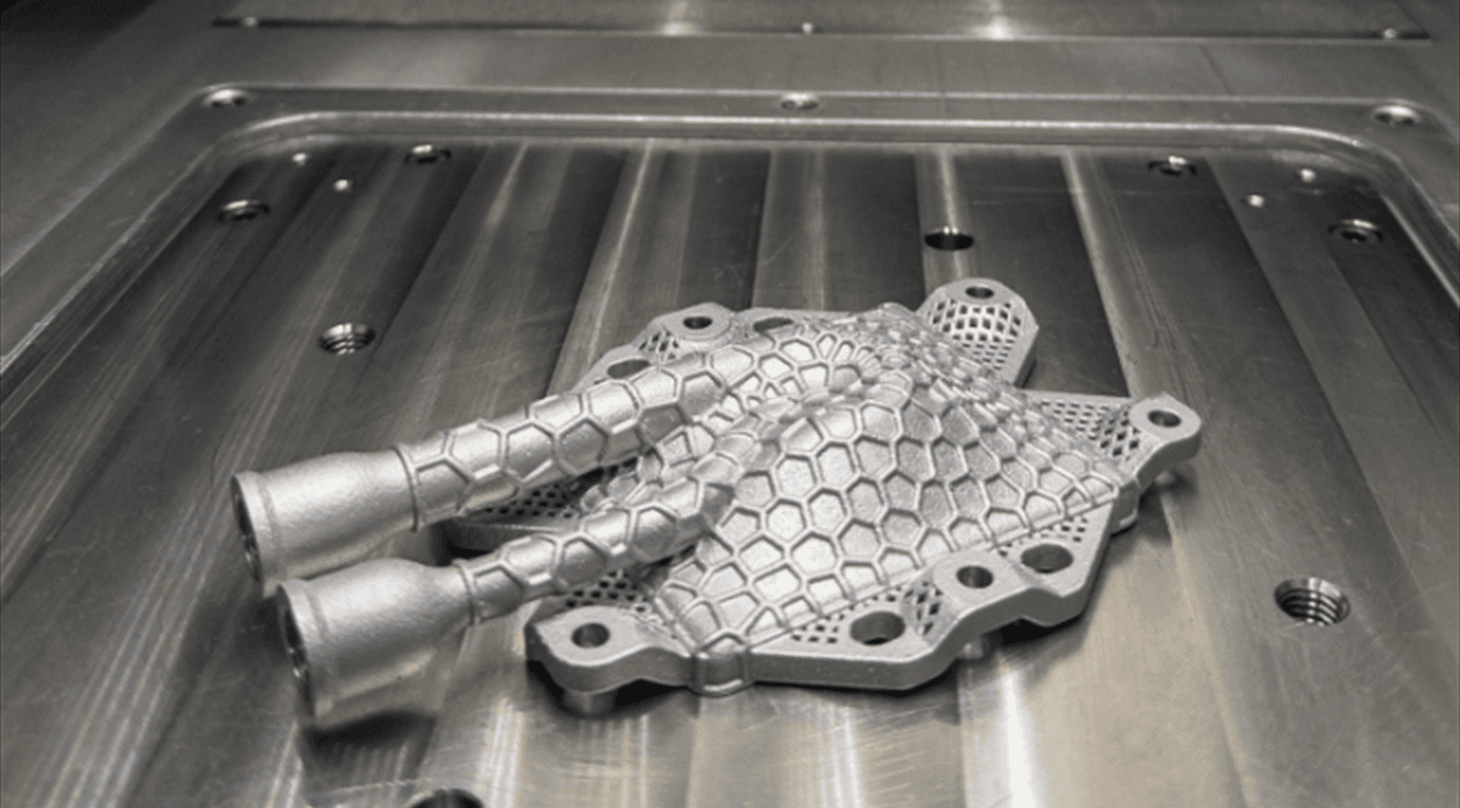

Quarterly calibration keeps prints dimensionally accurate. Calibrate E-steps and flow so extruded volume matches slicer settings and filament diameter. Check bed-leveling probe height and confirm first-layer consistency across the build plate; uneven first layers are the most common precursor to failed prints. Inspect PTFE Bowden tubes visually and feel for softening or blackened ends; replace Bowden tubing if it looks degraded to avoid intermittent clogs and poor retraction behavior.

Filament storage matters as much as hardware care. Keep Nylon, PETG, and specialty filaments desiccated in dry boxes or vacuum-sealed bags with desiccant to prevent moisture absorption that causes bubble extrusion and weak prints. Rotate stock so older spools are used before they degrade, and label spools with purchase or opening dates when possible.

Safety and spares reduce downtime. Keep spare nozzles of common sizes, a basic tool kit, and the printer's original maintenance manual on hand so repairs follow manufacturer tolerances. A few replacement parts and clean tools turn a repair that would take hours into a quick intervention.

A simple, consistent routine delivers the biggest returns: weekly checks prevent surprise failures, monthly inspections catch mechanical drift, and quarterly calibrations preserve dimensional fidelity. Follow these steps and a modest investment of time and a few spare parts will keep the printer running, the filament printable, and community print runs on schedule.

Know something we missed? Have a correction or additional information?

Submit a Tip