Nagoya team develops printable, heat-resistant aluminum alloys for LPBF

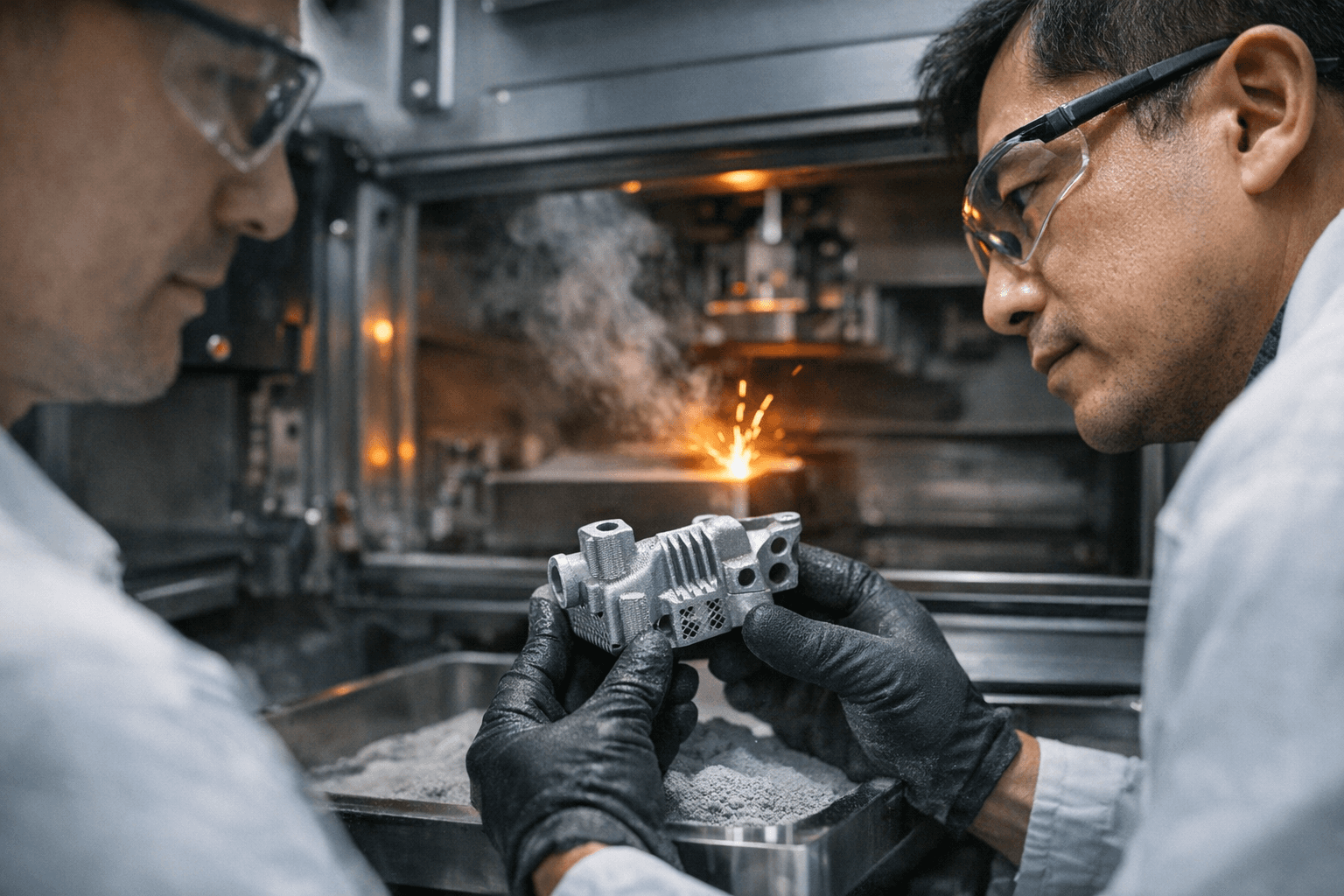

Researchers unveiled aluminum alloys for LPBF that blend high-temperature strength, recyclability and reliable printability, opening new uses for metal 3D printing.

Researchers at Nagoya University reported a new family of aluminum alloys tailored for laser powder bed fusion (LPBF) that combine elevated heat resistance with recyclability and robust printability. The team targeted a persistent barrier in metal additive manufacturing: aluminum grades that print well but lose strength at temperature, or retain strength but refuse to behave in the melt pool.

Rather than adapting casting or wrought alloys, the researchers used a materials-by-design approach for AM. They intentionally added iron, along with elements such as manganese, titanium and copper, to promote metastable microstructures during the rapid solidification inherent to LPBF. An example composition described as Al-Fe-Mn-Ti reportedly balances room-temperature ductility with enhanced high-temperature strength while printing more reliably than many existing high-strength aluminum alloys.

For the maker community, the practical value is clear. Aluminum is prized for low weight, but its performance at elevated temperatures has limited uses in engine-adjacent and under-hood environments. These new alloy formulations could let you print lighter parts that tolerate hotter operating conditions—think compressor rotors, components near turbines, or automotive pieces exposed to sustained heat—without immediately turning to heavier steels or specialized nickel alloys.

Recyclability is another headline. The alloys were developed with powder reuse in mind, an essential factor for circular manufacturing and cost control. Reliable reuse of feedstock can reduce waste, lower material costs for small-batch runs and hobby-scale production, and simplify shop workflows that rely on repeated powder cycles.

Technical implications extend beyond a single composition. Demonstrating that alloy design tuned for LPBF microstructures can deliver both ductility and high-temperature strength strengthens the case for AM-specific metallurgy. That shifts development away from retrofitting traditional alloys toward creating feedstocks engineered around LPBF's high cooling rates and localized thermal cycles.

What you can expect next is additional validation and scaling. Laboratory reports usually precede industry testing for fatigue life, oxidation resistance, post-processing behavior and qualification under service conditions. Certification for critical applications will take longer, but designers and small manufacturers can start planning how these alloys might change part geometry, weight targets and thermal margins.

This development broadens the toolbox for metal 3D printing: more aluminum options that print well, stand up to heat, and fit a circular workflow. Keep an eye on follow-up testing and new feedstock offerings—these alloys could make heat-tolerant, lightweight metal printing a lot more accessible.

Sources:

Know something we missed? Have a correction or additional information?

Submit a Tip