3D-Printed Aluminum Evaporator Delivers Pump-Free 600W Thermosiphon Cooling, Enables Heat Reuse

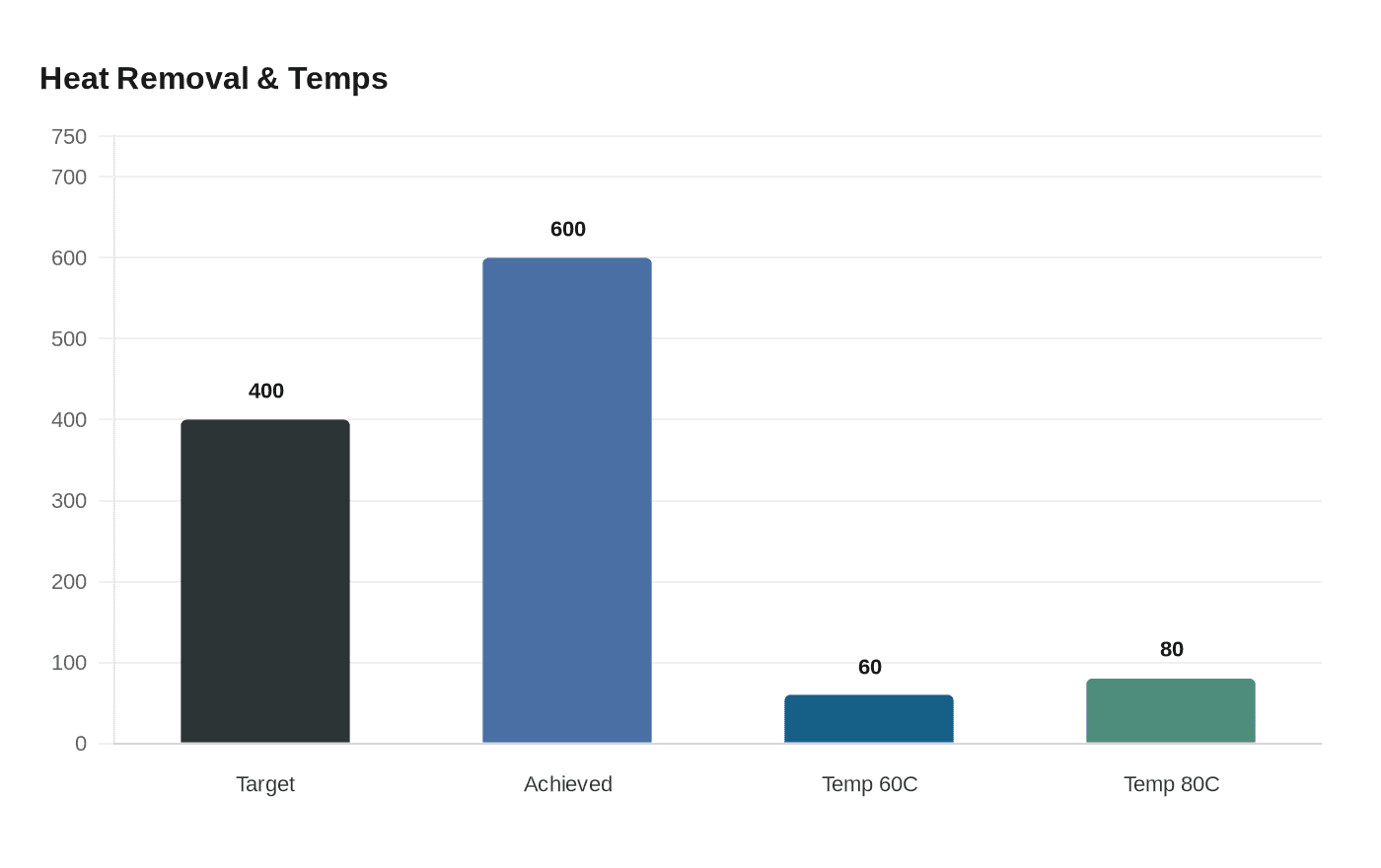

A 3D-printed aluminium evaporator removed up to 600 W using pump-free thermosiphon cooling, cutting energy use and producing 60–80 °C exhaust suitable for heat reuse.

A consortium led by the Danish Technological Institute and Heatflow demonstrated a 3D-printed aluminium evaporator that delivered passive two-phase thermosiphon cooling for data center and high performance computing (HPC) applications. The AM2PC project device removed up to about 600 W in testing, roughly 50% above the original 400 W target, and did so without pumps or fans.

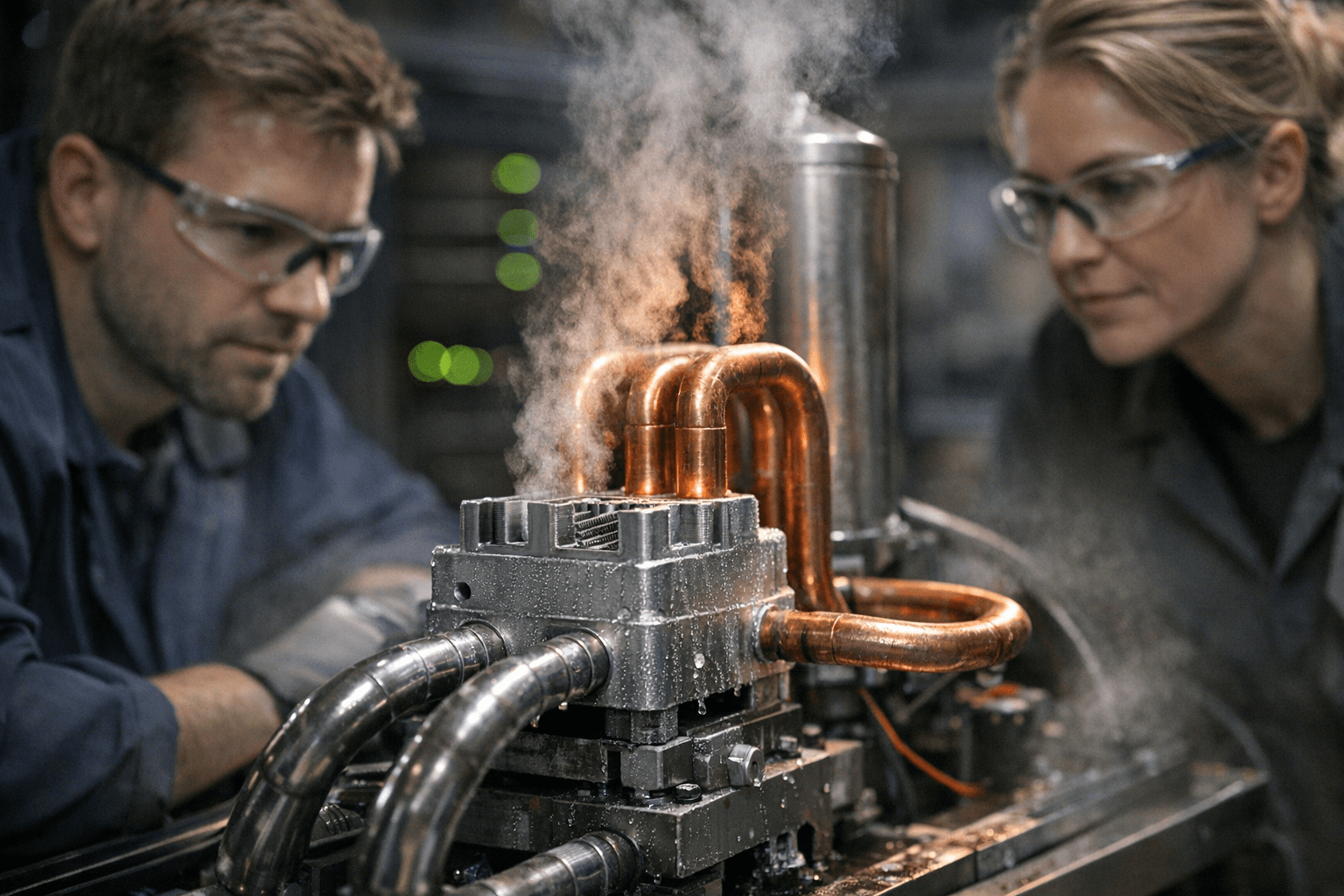

The evaporator uses the thermosiphon principle: liquid cools and evaporates at the hot surface, vapor rises to a condenser, and condensed liquid returns by gravity. That simple closed-loop removes heat without active pumping, which lowers operational electricity demand for cooling. Exhaust temperatures measured at roughly 60–80 °C are high enough to be routed into district heating networks or used for industrial low-temperature processes, turning waste heat into a resource.

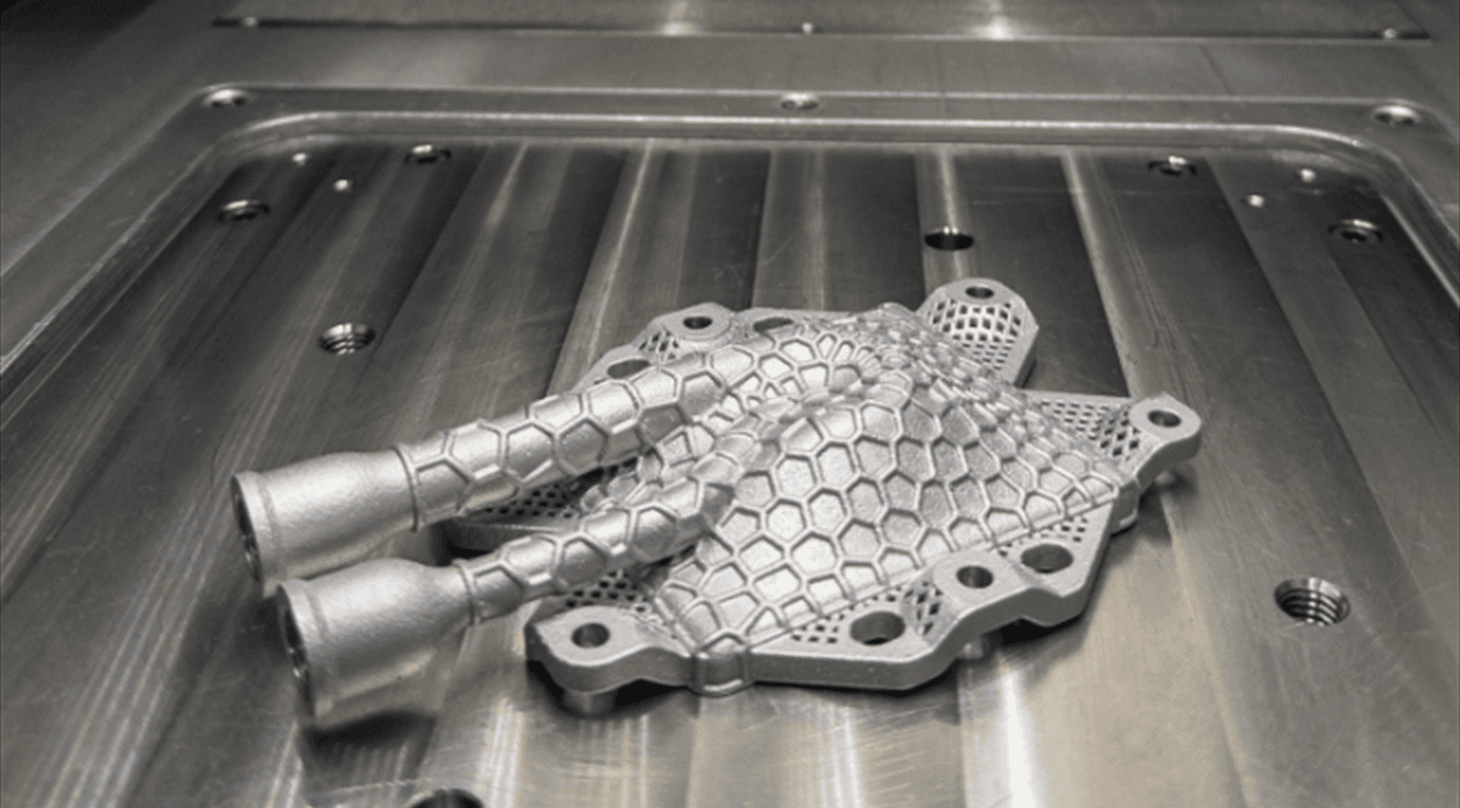

The part itself is an integrated single-material aluminium component produced by additive manufacturing. By printing a metal evaporator as one piece, the design reduces assembly steps and eliminates many gasket and joint interfaces that commonly cause leaks in traditional water-cooled systems. For facilities that manage leak risk tightly, a single-metal solution simplifies mechanical integration and service logistics.

Testing under the AM2PC project showed the device exceeded expectations on raw heat removal. That performance matters because cooling often accounts for a large share of a data center’s energy bill; passive two-phase approaches can reduce that load and shrink cooling system complexity. Lifecycle analyses conducted for the project indicate potential reductions in both energy use and greenhouse gas emissions when these components are deployed at scale, although full system-level studies will be needed to quantify savings for specific rack and facility architectures.

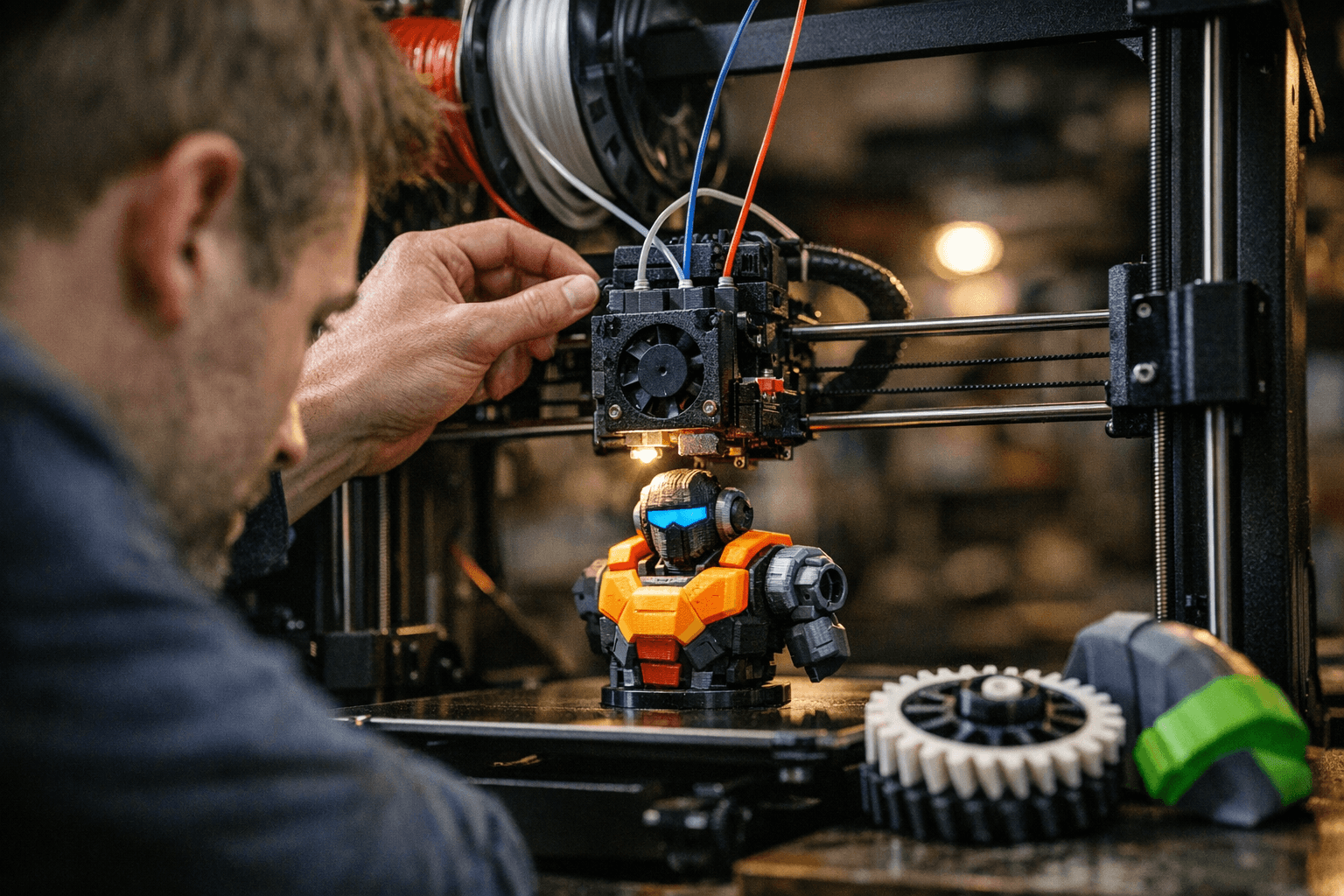

For the 3D printing community, the demonstration highlights additive manufacturing’s ability to produce functional, high-performance metal cooling hardware that would be difficult to manufacture conventionally. The aluminium material choice balances thermal conductivity, corrosion resistance, and AM process maturity, making it attractive for rapid prototyping and series production.

Practical next steps include integrating printed evaporators into rack-level thermal designs, validating long-term reliability in production loads, and designing condensers and heat-recovery plumbing to capture the 60–80 °C exhaust. For anyone planning upgrades or experiments, consider compatibility with existing cold plates, condenser placement, and building heat-reuse pathways. The AM2PC result shifts the conversation from proof of concept to systems integration, opening a route to lower-energy cooling and actual heat reuse in data centers and HPC setups.

Know something we missed? Have a correction or additional information?

Submit a Tip