Roboze Opens El Segundo HQ to Industrialise Aerospace Polymer AM Supply Chains

Roboze opens El Segundo HQ to industrialise aerospace polymer AM supply chains and speed qualification and local production of ULTEM/PEI and composite parts.

Roboze opened a new US Aerospace & Defence headquarters in El Segundo, California on January 22, 2026, positioning the company near aerospace and defence OEMs and prime contractors to accelerate industrialisation of polymer additive manufacturing. The facility targets faster application development, qualification, and localized production of high-performance polymer and composite parts for mission-critical programs.

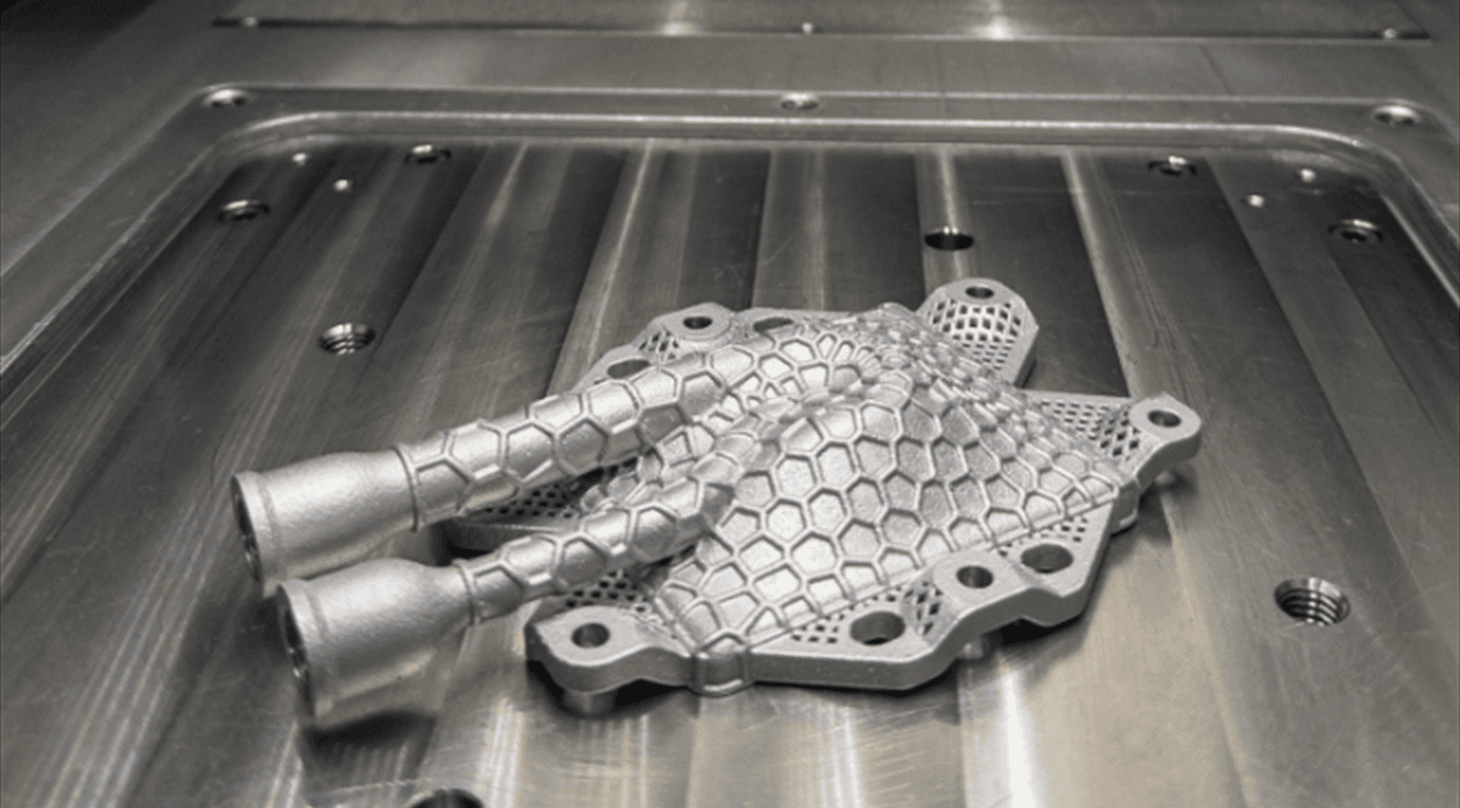

The El Segundo site focuses on materials such as ULTEM/PEI and aerospace-grade composites, where process control, repeatability, and traceable documentation matter as much as part geometry. Roboze says the location will support recruitment of highly skilled engineers and staff and enable closer, faster collaboration on industrialisation and qualification efforts. Those are practical priorities for programs that require certified parts rather than just prototype prints.

For the 3D printing community, the move signals a push from lab-scale experimentation toward production-grade, flight-ready components. Qualification for aerospace use typically demands extensive material testing, process validation, dimensional control, and supply-chain traceability. A local hub that concentrates engineering talent, material expertise, and direct lines to OEMs and primes can shorten feedback loops between design, test, and approved production runs. That reduces lead times and the logistical friction of cross-border supply chains for polymer AM parts.

Local supply-chain sovereignty underpins Roboze’s investment. By centralizing development and qualification in Southern California, Roboze aims to offer a domestic source for high-performance polymer parts that programs can trust. That matters where procurement rules, export controls, and long-term sustainment favor domestic manufacturing or validated local sources.

The facility also creates new collaboration opportunities for service bureaus, materials suppliers, test labs, and system integrators. Closer proximity to prime contractors makes direct qualification programs more feasible, from build-parameter locking to non-destructive inspection workflows and life-cycle documentation. For engineers and AM specialists, El Segundo could become a node for hands-on development of process recipes for ULTEM/PEI and composite feedstocks and for scaling single-part proofs into qualified batches.

Roboze’s announcement marks a step in the industry’s maturation: moving beyond proof-of-concept prints to certified, mission-capable polymer components. Expect announcements about hiring, qualification milestones, and joint development programs in the months ahead. For engineers, suppliers, and procurement teams tracking polymer AM for aerospace, the new El Segundo headquarters offers tangible promise of shorter qualification cycles, more local capacity, and a clearer path from the build plate to flight-ready hardware.

Know something we missed? Have a correction or additional information?

Submit a Tip