Design for Additive Manufacturing: Process Selection, Minimum Feature Sizes, Part Consolidation

Designers must match the right AM process to part needs - tolerances, materials and surface finish drive choices that affect feature sizes and whether to consolidate parts.

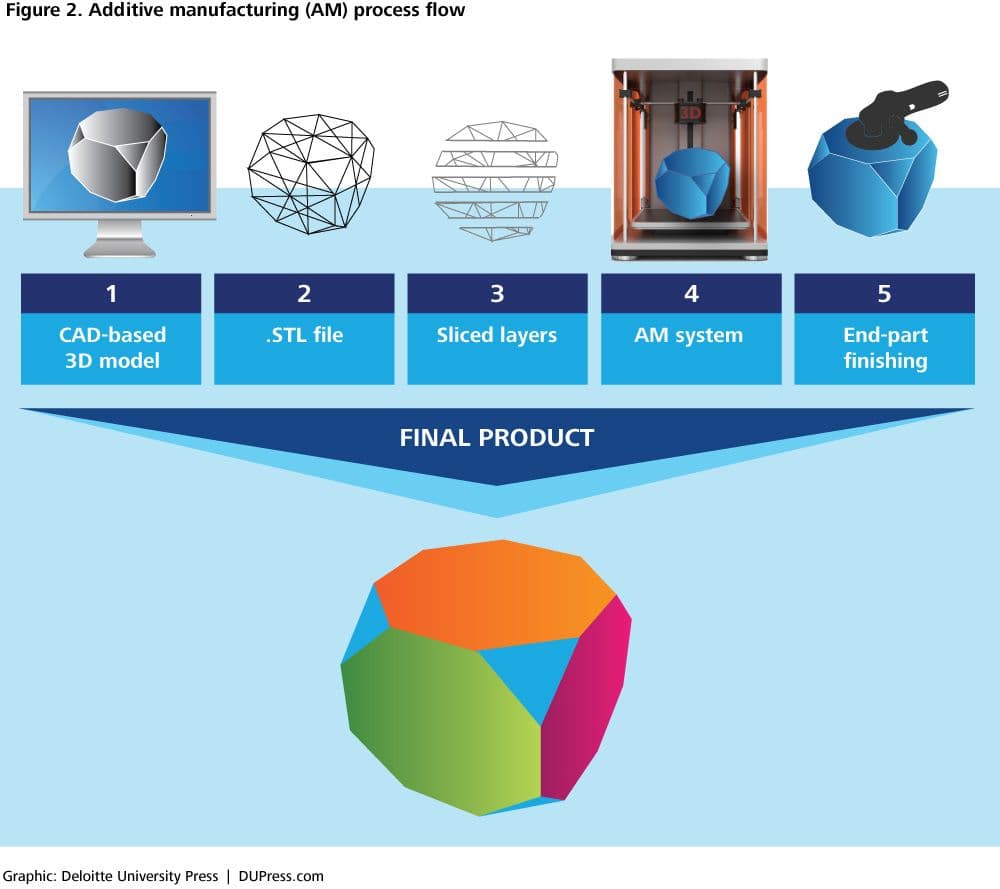

Additive manufacturing has moved from hobby bench to shop floor, and the design decisions you make up front now determine whether a 3D printed part will be a prototype or a production-ready component. Vendors tout faster lead times and cost savings, but standards bodies and practical limits still govern how far you can push geometry, materials and fit.

Start with process selection. Common options include FDM, SLA, SLS, binder jet, MJF and LPBF, and each brings distinct strengths for material choices, surface finish and feature resolution. Standards guidance from ASTM F42 and ISO TC 261 underlines that this choice should follow an analysis of the part’s needs: "Determine the AM process: once the previous key factors have been analysed, AM technique must be" - the fragment points to a sequence designers already know intuitively: define tolerances, materials and finish, then pick the process that meets them.

Tolerances and accuracy remain a practical limiter. As the committee text warns, "Know the dimensional and geometrical tolerances: AM technologies are not as accurate as traditional methods, thus areas of the geometry where fine adjustments or very specific geometrical and dimensional tolerances are demanded, will require to be post processed. A good understanding of these limitations will allow us to focus our design thinking not only in the part construction, but also in the post processing steps, clamping areas, and so on." In short, expect to design for postprocessing and clamping when tight fits or precision surfaces are required.

Material choice is equally strategic. The standards fragment counsels: "Know the raw material: we can find that in some occasions, parts are being manufactured in materials that are not necessary just because the production ratios make inefficient processes as injection moulding. (These methods require high productions in order to amortize the mould costs. Therefore, it is highly recommended to analyze the material [...] Therefore, it is highly recommended to analyze the material to be used for the part construction, sometimes a part which was initially conceived in metal-based materials, can be produced in polymeric materials by additive manufacturing.)" Evaluate mechanical needs before defaulting to the original material concept.

Surface finish is a design variable, not an afterthought. The standards text is blunt: "Know the surface finishes: due to the layer by layer method of the AM processes, parts produced by these techniques present an important surface roughness that sometimes is detrimental in the final parts, just because the mechanical properties are slightly affected or because the part appearance is compromised. Thus, surface finish must be defined so as to determine which kind of postprocessing tasks will be applied and of course it will affect the DfAM."

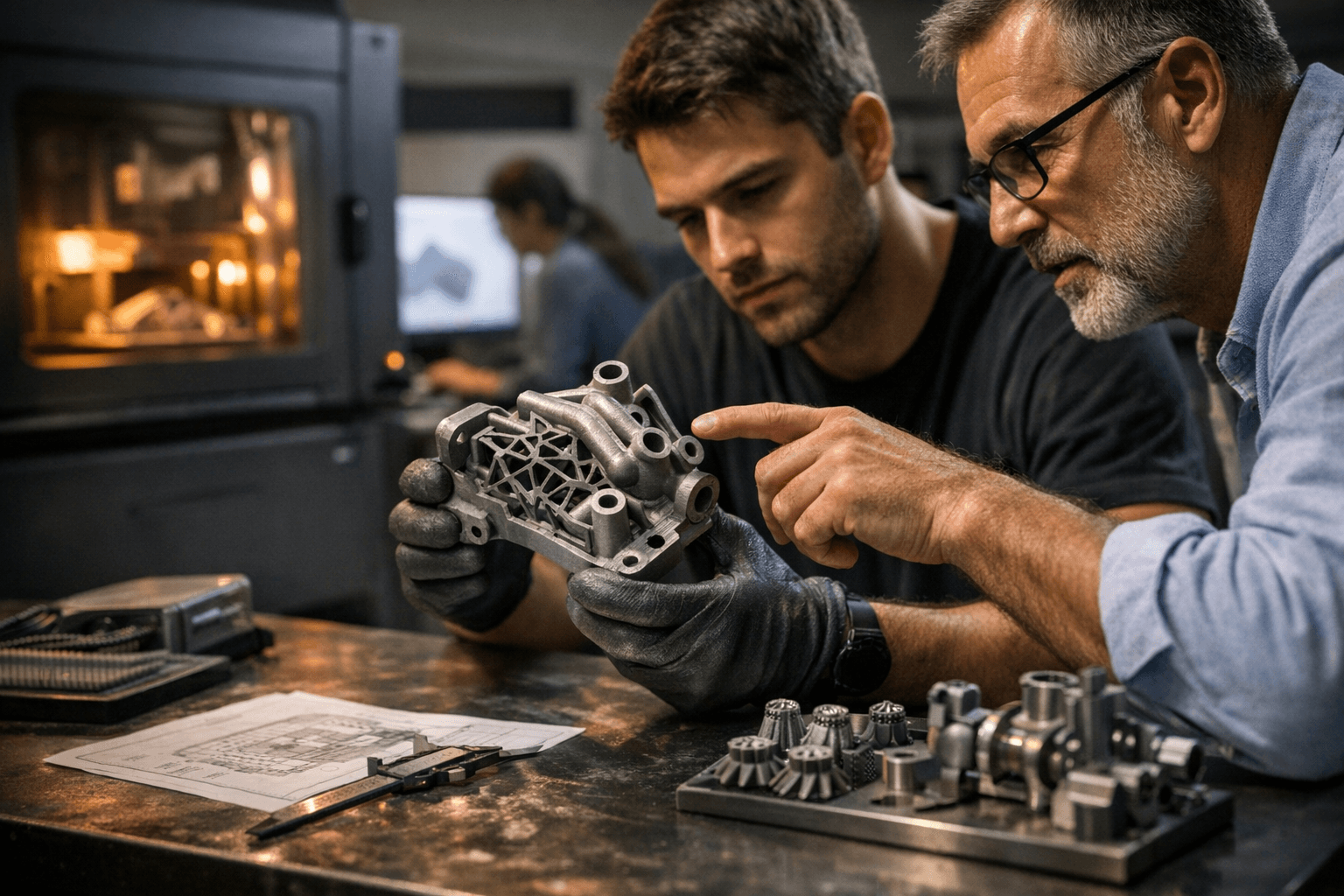

Design freedom and consolidation are the upside. Manufacturer materials highlight that "3D printing can produce complex geometries that are not achievable through other manufacturing techniques" and enable fewer parts and simpler assemblies when topology optimization and internal lattices displace bolted joints. Markforged frames the business case with strong claims: "3D printing tooling for production can save manufacturers tens of thousands of dollars per month compared to machining. For most manufacturers, additive manufacturing platforms will yield a near-immediate ROI: within months, or even weeks." The company also notes the federal AM Forward program launched in May 2022, which has injected further momentum into production adoption.

What this means for makers and small shops is practical: define your tolerances, pick a process that can meet them, decide surface finish and postprocessing up front, and look for opportunities to consolidate assemblies. Consult ASTM F42/ISO TC 261 guidance and vendor process datasheets for numeric limits on minimum wall thickness, minimum feature size and orientation effects before you finalise a design. The payoff is faster cycles, fewer parts and, when done correctly, a part that moves cleanly from slicer to service.

Know something we missed? Have a correction or additional information?

Submit a Tip