Intrepid Automation, Rapid Fluidics Partner to Scale U.S. Microfluidic Manufacturing

Intrepid Automation will be Rapid Fluidics’ exclusive U.S. manufacturing partner for microfluidics, a move aimed at scaling compliant, high-volume 3D-printed microfluidic production.

Intrepid Automation and Rapid Fluidics announced a strategic partnership to move microfluidic designs from prototype to U.S.-based production, combining Rapid Fluidics’ design and prototyping expertise with Intrepid’s scalable additive manufacturing systems. The agreement names Intrepid as Rapid Fluidics’ exclusive U.S. manufacturing partner for microfluidics and targets faster, more cost-effective production for healthcare and industrial applications.

Intrepid, a San Diego-based provider of industrial additive manufacturing solutions, will leverage ISO 13485 and ISO 9001 certified facilities to meet regulatory and quality-management needs for medical and diagnostic components. Rapid Fluidics, described in company materials as U.K.-based and a market leader in microfluidic design and rapid-production services, will supply the design pipeline and prototyping know-how while Intrepid focuses on scale-up and volume output.

“Rapid Fluidics brings deep expertise in microfluidics, and our scalable 3D printing systems allow those innovations to reach mass production without compromise,” said Ben Wynne, President and CTO of Intrepid Automation. “This partnership isn’t just about speed, but rather quality, regulatory compliance, and creating a foundation for future growth in several sectors, from healthcare to industrial applications.”

The partnership promises to close a common gap for labs and small developers: the jump from bench prototypes to compliant manufacturing. Intrepid’s ISO-certified facilities aim to marry quality systems with additive production capacity, allowing projects that once relied on offshore tooling or slow contract runs to stay closer to U.S. engineering and regulatory teams. Company-reported early case studies claim additive workflows have cut production timelines for certain high-throughput microfluidic systems from six weeks to two minutes while reducing material usage and complexity; those metrics are presented as early, company-related results.

The corporate backdrop includes a recent leadership change at Intrepid. Rich Carone was appointed CEO and is described as a manufacturing and automation veteran with more than five decades of experience. Company materials also note Ben Wynne’s continued role leading product innovation and partnerships, though reporting varies on his exact title; materials variously list him as President and CTO or as former CEO now serving as CTO.

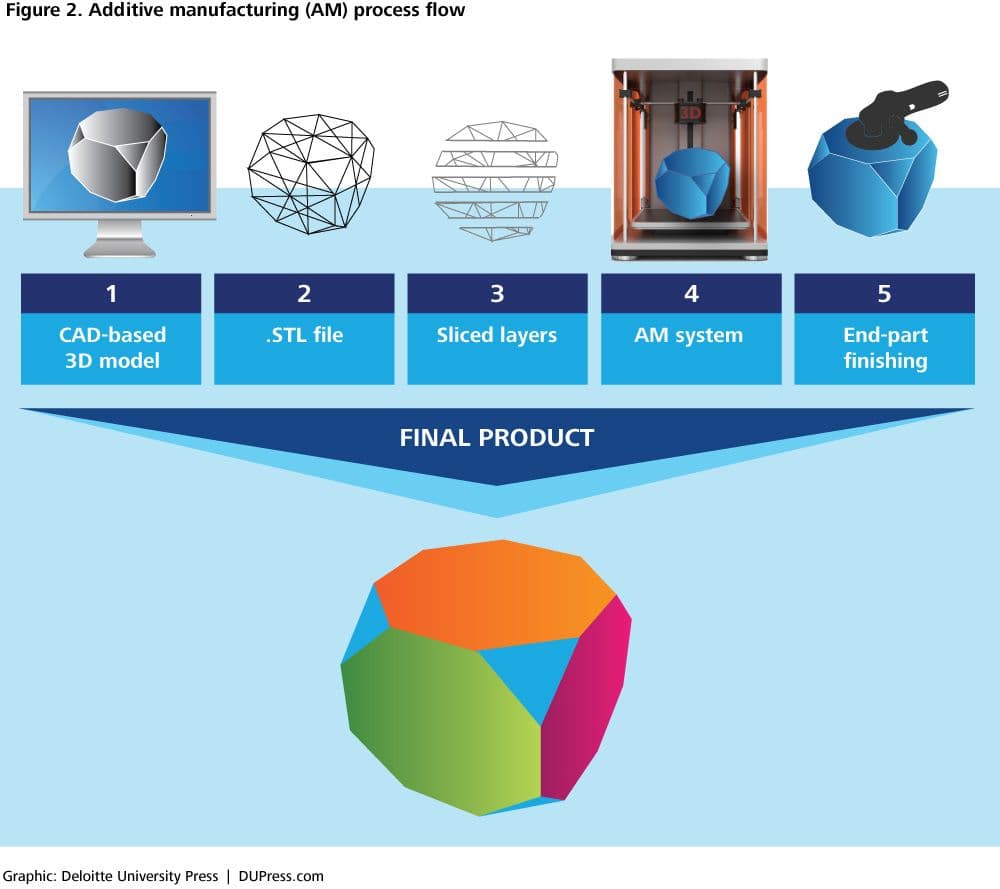

For the 3D printing and maker community, the deal signals growing demand for production-grade additive workflows that meet medical device quality standards. Designers working on labs-on-chip, point-of-care diagnostics, or industrial microfluidic fixtures can now envision a clearer path from iterative SLA or DLP prototyping to ISO-aligned, U.S.-based production runs and print-farm scale-up without immediate recourse to injection molding.

Next steps include watching for detailed production timelines, declared throughput numbers, and technical notes that explain the case-study methods behind the dramatic time-savings claim. Expect Intrepid and Rapid Fluidics to publish more specifics on materials, printer platforms, and which assembly and test steps will remain domestic as deployments ramp. For designers and small manufacturers, this partnership could shorten lead times and smooth regulatory pathways as microfluidic products move toward wider commercial use.

Know something we missed? Have a correction or additional information?

Submit a Tip